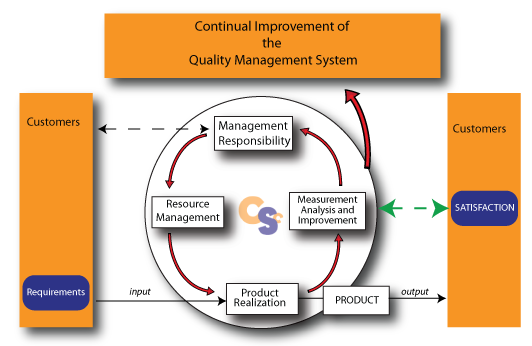

Quality Management Systems

We are experts in the development of Quality Management Systems for Geoscience, Nuclear, Environmental, Architecture and Information Technology - however the application of Quality Management is industry agnostic. The fundamental elements of Quality Management Systems flood through all successful enterprises.

We are experts in multiple disciplines - We are System Builders.

- Developed a 10-CFR-50, NQA-1, compliant Quality Assurance Program for Nye County Nevada Nuclear Waste Repository Scientific Program – only local level Program ever accepted by the US Nuclear Regulatory Commission at the time.

- Performed ground breaking integration of nuclear regulations for building power plants into the management of geoscience investigations.

- Lead a recertification program for US Department of Energy on the Yucca Mountain High-Level Nuclear Waste Program that resulted in the rescue of a half billion dollars in geologic samples and associated data.

- Designed a business intelligence (BI) solution for a key client with a 6-month ROI of $1M by implementing real-time BI on 25,000 VARs and meeting real-time inventory demands geographically.

- Saved $2.8M on the initial budget by persuading the CFO that the vendor was overcharging client for services, which led to the selection of a new vendor with additional savings on the entire project.

- Provided critical support during the rollout of Platinum Services in Japan and Korea through collaborating with the entire Dell Japan and Dell Korea technical account management organizations (Dell, Inc.).

Quality is simply good management, good management is the use of planned and systematic actions necessary to provide adequate confidence that a structure, system or component will perform satisfactory in service.

-

- List of Publications

- White Papers

PUBLICATIONS - E. Dow Davidson

Papers

E. Dow Davidson, August 2011, Facility Storage Sizing Principles For Diamond Drilled Core Collections, white paper prepared for Curatorial Science Consultants, Leander, Texas, 5 p.

E. Dow Davidson, August 2011, Facility Storage Sizing Calculations Based On Volumetric Measurements of Geologic Sample Collections, white paper prepared for Curatorial Science Consultants, Leander, Texas, 6 p.

Sinks, Donna. J., E. Dow Davidson, Jr., September 1992, Sample Management for Environmental Restoration Programs, paper presented at Geo Tech '92 conference, Denver Colorado, 8 p.

Technical Reports

Shulte, B, and Davidson, E. D. Jr.: 2006, Geologic Materials Center Concept Study: USKH Inc, Architecture, Engineering, Land Surveying, Planning, Concept Study for the State of Alaska, Department of Transportation and Public Facilities Central Region, ASKAS# 57658, 80p.

Carlton, C. D., Cleghorn, P., Davidson, E. D. Jr., Miller G., Murabayashi, D. H., Murabayashi, J., Pantaleo, J. J., Riford, M. F., Sinoto, A., Taguchi, L, and Yuen, W. W. L.; 1991, Hawaiian Fishpond Study - Islands of Hawai'i, Maui, Lana'i and Kaua’i: DHM Inc. and Applied Research Group, Public Archaeology Section, Bishop Museum, 199 P., report prepared for The Hawaii Coastal Zone Management Program, Office of State Planning, Office of the Governor through the State Department of Land and Natural Resources - Historic Preservation Division.

Carlton, C. D., Cleghorn, P., Davidson, E. D. Jr., Miller G., Murabayashi, D. H., Murabayashi, J., Pantaleo, J. J., Riford, M. F., Sinoto, A., Taguchi, L, and Yuen, W. W. L.; 1991, Maui, Lana'i and Kaua'i In-depth Studies, Hawaiian Fishpond Study: DHM Inc. and Applied Research Group, Public Archaeology Section, Bishop Museum, 220 P., report prepared for The Hawaii Coastal Zone Management Program, Office of State Planning, Office of the Governor through the State Department of Land and Natural Resources - Historic Preservation Division.

Carlton, C. D., Cleghorn, P., Davidson, E. D. Jr., Miller G., Murabayashi, D. H., Murabayashi, J., Pantaleo, J. J., Riford, M. F., Sinoto, A., Taguchi, L., and Yuen, W. W. L.; 1991, Hawai'i In-depth Studies, Hawaiian Fishpond Study: DHM Inc. and Applied Research Group, Public Archaeology Section, Bishop Museum, 380 P., report prepared for The Hawaii Coastal Zone Management Program, Office of State Planning, Office of the Governor through the State Department of Land and Natural Resources - Historic Preservation Division.

Davidson, E. D., Jr., 1981, Establishing a continental curatorial communications network, in Goff, Sue, and Heiken, Grant eds., Workshop on core and sample curation for the National Continental Scientific Drilling Program: Los Alamos National Laboratory, p. 23-24.

Davidson, E. D., Donaldson, G. A., and Seni, S. J., 1981, Handling procedures for Wilcox core from LETCO TOH-2AO near Oakwood Dome, East Texas basin, p. 195, in Kreitler, C. W., Collins, E. W., Davidson, E. D., Jr., Dix, O. R., Donaldson, G. A., Dutton, S. P., Fogg, G. E., Giles, A. B., Harris, D. W., Jackson, M. P. A., Lopez, C. M., McGowen, M. K., Muehlberger, W. R., Pennington, W. D., Seni, S. J., Wood, D. H., and Wuerch, H. V., Geology and geology of the East Texas Basin, a report on the progress of the progress of nuclear waste isolation feasibilities studies (1980): The University of Texas at Austin, Bureau of Economic Geology Geological Circular 81-7, 207 p.

QA Plans, Procedures,

Davidson, E. D., Jr., 2001, Quality Assurance Program Plan: QA plan prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 37p.

Davidson, E. D., Jr., 2002, Work Plan 8, Sample Management Plan for Early Warming Drilling Program: QA Work Plan prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 10 p.

Davidson, E. D., Jr., 1995, QAP-3.1, Procedures for Independent Review: Quality Administrative Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 5 p.

Davidson, E. D., Jr., 2001, QAP-3.2, Procedures for Documentation of Scientific Investigations: Quality Administrative Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 11 p.

Davidson, E. D., Jr., 1995, QAP-5.1, Preparation of Quality Administrative Procedures: Quality Administrative Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 9 p.

Davidson, E. D., Jr., 2001, QAP-5.2, Preparation of Work Plans and Technical Procedures: Quality Administrative Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 18 p.

Davidson, E. D., Jr., 2001, QAP-6.1, Procedures for Issuance and Control of Quality Assurance Documents: Quality Administrative Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 9 p.

Davidson, E. D., Jr., 1995, QAP-7.1, Procedures for Issuance and Control of Quality Assurance Documents: Quality Administrative Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 5 p.

Davidson, E. D., Jr., 1995, QAP-8.1, Procedures for Sample Management: Quality Administrative Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 4 p.

Davidson, E. D., Jr., 1995, QAP-16.1, Procedures for Corrective Action: Quality Administrative Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 5 p.

Davidson, E. D., Jr., 1997, QAP-17.1, Quality Assurance Records Management Procedures: Quality Administrative Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 8 p.

Davidson, E. D., Jr., 1995, QAP-18.1, Procedures for Quality Assurance Audits and Surveillances: Quality Administrative Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 10 p.

Davidson, E. D., Jr., 2001, TP-7.0, Drill Site Management: QA Technical Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 12 p.

Davidson, E. D., Jr., 2002, TP-8.0, Field Logging and Handling of Borehole Samples: QA Technical Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 36 p.

Davidson, E. D., Jr., 2002, TP-9.9, Measurement of Groundwater levels: QA Technical Procedure prepared for Nye County Nuclear Waste Repository Project Office, Nye County Nevada, Independent Scientific Investigation Program, 9 p.

Davidson, E. D., Jr., 1994, Field logging, Handling, and Documentation of Borehole Materials: technical procedure prepared for University of California, Los Alamos National Laboratory, Environmental Restoration Program, 27 p.

Davidson, E. D., Jr., 1994, Transportation, Receipt, And, Admittance Of Borehole Samples For The Sample Management Facility: technical procedure prepared for University of California, Los Alamos National Laboratory, Environmental Restoration Program, 13 p.

Davidson, E. D., Jr., 1994, Acceptance of Non-borehole Samples By The Sample Management Facility: technical procedure prepared for University of California, Los Alamos National Laboratory, Environmental Restoration Program, 7 p.

Davidson, E. D., Jr., 1994, Physical Processing and Storage of Borehole Samples At The Sample Management Facility: technical procedure prepared for University of California, Los Alamos National Laboratory, Environmental Restoration Program, 16 p.

Davidson, E. D., Jr., 1994, Examination of Samples At The Sample Management Facility: technical procedure prepared for University of California, Los Alamos National Laboratory, Environmental Restoration Program, 7 p.

Michelotti, R., Et al; 1993, Chapter 5, Appendix D in RCRA Facility Investigation (RFI) Work Plan for the Operable Unit 1147: Los Alamos National Laboratory Environmental Restoration Program

Hakonson, T., Et al; 1992, Chapter 5 in RCRA Facility Investigation (RFI) Work Plan for the Operable Unit 1147: Los Alamos National Laboratory Environmental Restoration Program

Davidson, E. D., Jr., Pantaleo, J.; 1991, Archaeological Survey of Pohoiki Geothermal Transmission Line No. 1 in Puna, Hawai'i Island: Applied Research Group, Public Archaeology Division, Bishop Museum, 13 p.

Davidson, E. D., Jr.; Pantaleo, J.; 1990, Phase I archaeological survey of three realignment areas, Hawaii Belt Road improvements, Ke'ei to Papa, Ahupua'a of 'Alika, Opihihale 2, and Kukuiopa'e 2, South Kona, Island of Hawaii: Applied Research Group, Public Archaeology Section, B. P. Bishop Museum, 33 p.

Clark, S. D.; Davidson, E. D.; and Cleghorn, P.; 1990, Archaeological testing and data recovery for the Waimea school improvements Lot A (TMK: 6-7-2: por. 17), Waikoloa, South Kohala, Hawai'i island: Applied Research Group, Public Archaeology Section, B. P. Bishop Museum, 48 p.

Davidson, E. D., Jr., Sinks, D. J., and Davis, J. H.,1989, Management and operations of sample handling activities at Yucca Mountain Project borehole sites: Science Applications International Corporation, administrative procedure prepared for US. Department of Energy, Yucca Mountain Project Office under contract no. DE-AC08-87NV10576, 10 p.

Davidson, E. D., Jr., Sinks, D. J., and Davis, J. H.,1989, Use of the Sample Management Facility by Yucca Mountain Project participants: Science Applications International Corporation, administrative procedure prepared for US. Department of Energy, Yucca Mountain Project Office under contract no. DE-AC08-87NV10576, 8 p.

Carlos, B. A., Davidson, E. D., Jr., and Stellavato, J. N.,1989, Field collection, documentation, and specimen removal of exploratory shaft and drift rock: Science Applications International Corporation, administrative procedure prepared for US. Department of Energy, Yucca Mountain Project Office under contract no. DE-AC08-87NV10576, 7 p.

Davidson, E. D., Jr., Sinks, D. J., and Davis, J. H.,1989, Management and operation of the Sample Management Facility: Science Applications International Corporation, technical procedure prepared for US. Department of Energy, Yucca Mountain Project Office under contract no. DE-AC08-87NV10576, 10 p.

Davidson, E. D., Jr., Donaldson, G. A., Davis, J. H., and, Sinks, D. J,1989, Transport, receipt and admittance for curation of Yucca Mountain Project borehole samples: Science Applications International Corporation, technical procedure prepared for US. Department of Energy, Yucca Mountain Project Office under contract no. DE-AC08-87NV10576, 7 p.

Davidson, E. D., Jr., and Donaldson, G. A.,1989, Physical processing and storage of Yucca Mountain Project core and cuttings: Science Applications International Corporation, technical procedure prepared for US. Department of Energy, Yucca Mountain Project Office under contract no. DE-AC08-87NV10576, 10 p.

Davidson, E. D., Jr., Sinks, D. J., and Davis, J. H.,1989, Examination of Yucca Mountain Project samples by participants: Science Applications International Corporation, technical procedure prepared for US. Department of Energy, Yucca Mountain Project Office under contract no. DE-AC08-87NV10576, 6 p.

Davidson, E. D., Jr., and Donaldson, G. A.,1989, Removal of whole core specimens and other specimens from Yucca Mountain Project samples for shipment and return: Science Applications International Corporation, technical procedure prepared for US. Department of Energy, Yucca Mountain Project Office under contract no. DE-AC08-87NV10576, 11 p.

Davidson, E. D., Jr., Sinks, D. J., and Davis, J. H.,1989, Acceptance for curation of selected Yucca Mountain Project samples and documentation: Science Applications International Corporation, technical procedure prepared for US. Department of Energy, Yucca Mountain Project Office under contract no. DE-AC08-87NV10576, 6 p.

Sinks, D. J., Davis, J. H., and Davidson, E. D., Jr., 1989, Field logging, handling, and documenting Yucca Mountain Project borehole samples: Science Applications International Corporation, technical procedure prepared for US. Department of Energy, Yucca Mountain Project Office under contract no. DE-AC08-87NV10576, 27 p.

Davidson, E. D., 1983, Procedures for test control: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651, 4 p.

Davidson, E. D., 1983, Instructions, procedures and drawings: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651, 4 p.

Davidson, E. D., 1983, Procedures for handling, storage and shipping: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651, 4 p.

Davidson, E. D., 1983, Procedures for document control: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651, 4 p.

Ratcliff, D. C., and Davidson, E. D., 1983, Quality Assurance Program: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651, 34 p.

Davidson, E. D., 1982, Procedures for control of measuring and testing equipment: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651, 7 p.

Davidson, E. D., 1982, Procedures for quality assurance audits: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651, 10 p.

Davidson, E. D., 1982, Inspection procedures for geologic material processing: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC9783WM46651, 10 p.

Ratcliff, D. C., Roberts, M. P., Orr, E. D., and Davidson, E. D., 1982, Documentation and traceability of published and unpublished computer-generated data: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651,10 p.

Ratcliff, D. C., and Davidson, E. D., 1982, Control of purchased equipment and services: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651, 7 p.

Ratcliff, D. C., and Davidson, E. D., 1982, Preparation, issue and control of quality assurance procedures: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651, 5 p.

Ratcliff, D. C., and Davidson, E. D., 1982, Control of drawings, figures and other drafted illustrations: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651, 7 p.

Ratcliff, D. C., Roberts, M. P., Orr, E. D., and Davidson, E. D., 1982, Quality assurance control of computer programs/software: The University of Texas at Austin, Bureau of Economic Geology, quality assurance procedure prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651,14 p.

Davidson, E. D., Schmedes, K. E., Plowman, M. K., and Donaldson, G. A.,1980, Basic procedures of the Well Sample and Core Library: The University of Texas at Austin, Bureau of Economic Geology, quality assurance booklet prepared for US. Department of Energy, under contract nos. DE-AC97-80ET46615 and DE-AC97-83WM46651,64 p.

White Papers - E. Dow Davidson

E. Dow Davidson, August 2011, Facility Storage Sizing Principles For Diamond Drilled Core Collections, white paper prepared for Curatorial Science Consultants, Leander, Texas, 5 p

E. Dow Davidson, August 2011, Facility Storage Sizing Calculations Based On Volumetric Measurements of Geologic Sample Collections, white paper prepared for Curatorial Science Consultants, Leander, Texas, 6 p.